Description

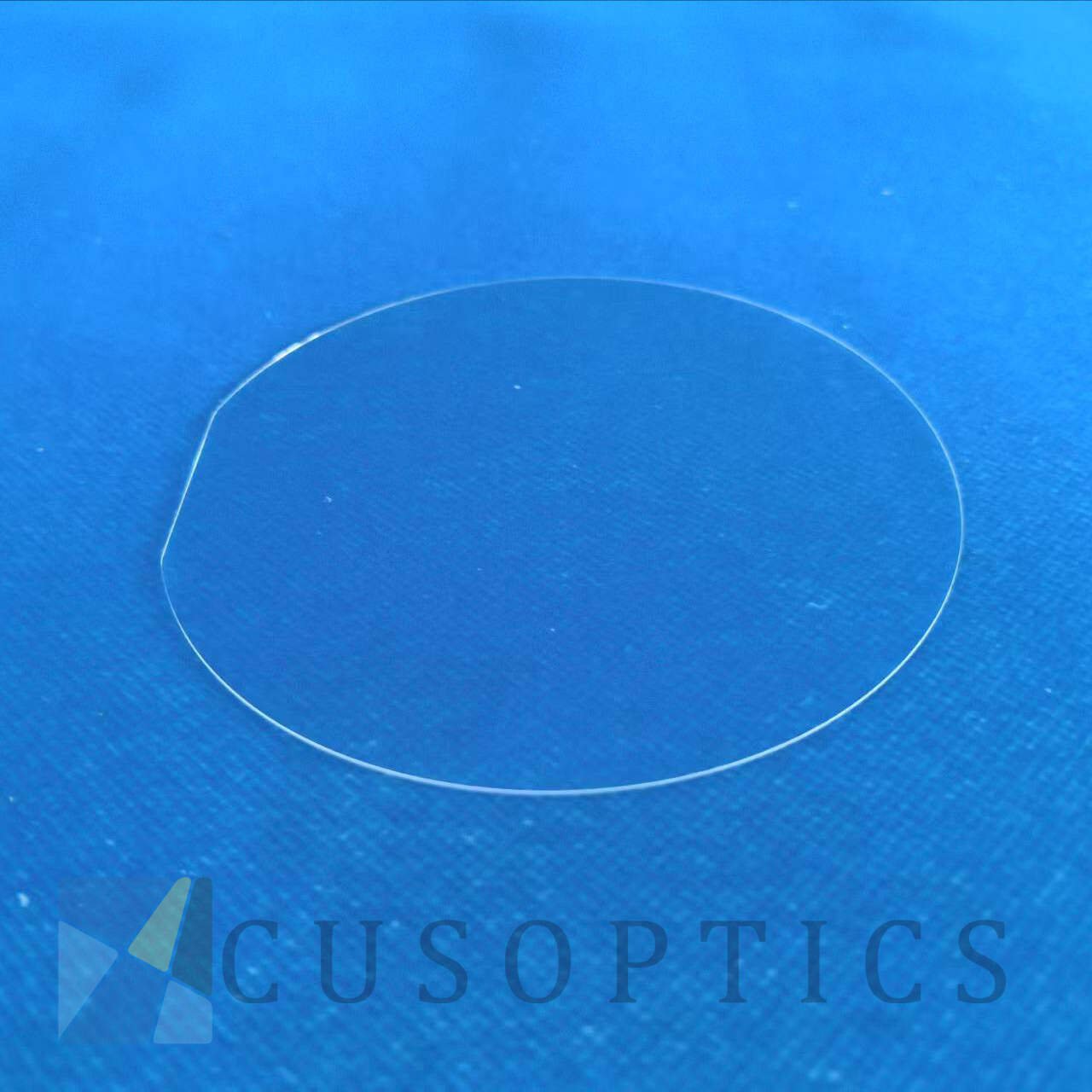

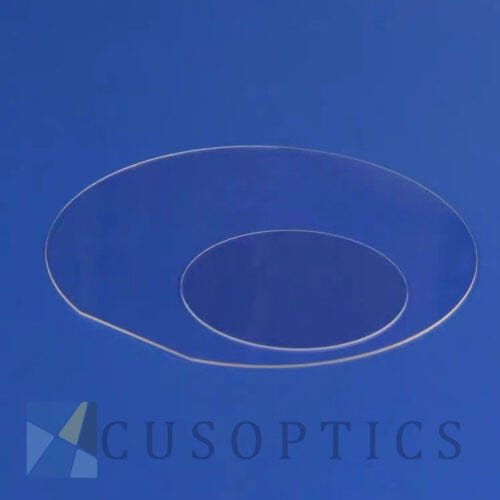

Large size crystal orientation C double-sided polished sapphire glass plate is a type of chip made from high-quality artificial sapphire single crystal ingots, cut along the c-axis direction, with a diameter usually ≥ 100mm (4 inches). Both main surfaces are ultra precision polished to achieve extremely high smoothness and flatness, and the edges are cut (chamfered) at specific angles to enhance strength.

Core values: Combining the excellent physical and chemical properties of sapphire (hardness, corrosion resistance, high temperature resistance, insulation, good light transmission), the key support of c-plane orientation for epitaxial growth, the perfect surface provided by double-sided polishing, the high reliability brought by corner cutting, and the high production efficiency brought by large size to meet the needs of large devices.

1. Sapphire:

This refers to artificially synthesized single crystal alpha alumina, with the chemical formula Al ₂ O3.

It has extremely high hardness (Mohs hardness 9, second only to diamond), excellent chemical stability (resistant to strong acid and alkali corrosion), outstanding high-temperature stability, good insulation, high melting point (about 2040 ° C), and high transparency in the visible to near-infrared wavelength range.

These characteristics make it an ideal material for harsh environments and high-performance applications.

2. Crystal orientation C:

This refers to the crystal orientation of sapphire chips.

C “usually refers to the c-axis direction or [0001] crystal orientation of sapphire. This is a very important symmetry axis in the hexagonal crystal system of sapphire crystals.

significance:

The basis of epitaxial growth: For applications that require thin film epitaxial growth, such as GaN based LEDs and microelectronic devices, the c-plane (0001 plane) is the most commonly used and mature substrate orientation. It can provide good lattice matching and surface properties, which is conducive to the growth of high-quality single crystal thin films.

Anisotropy: The physical properties of sapphire, such as hardness, coefficient of thermal expansion, and chemical etching rate, vary in different crystal orientations. Choosing the c-plane is to utilize its optimal performance in a specific direction.

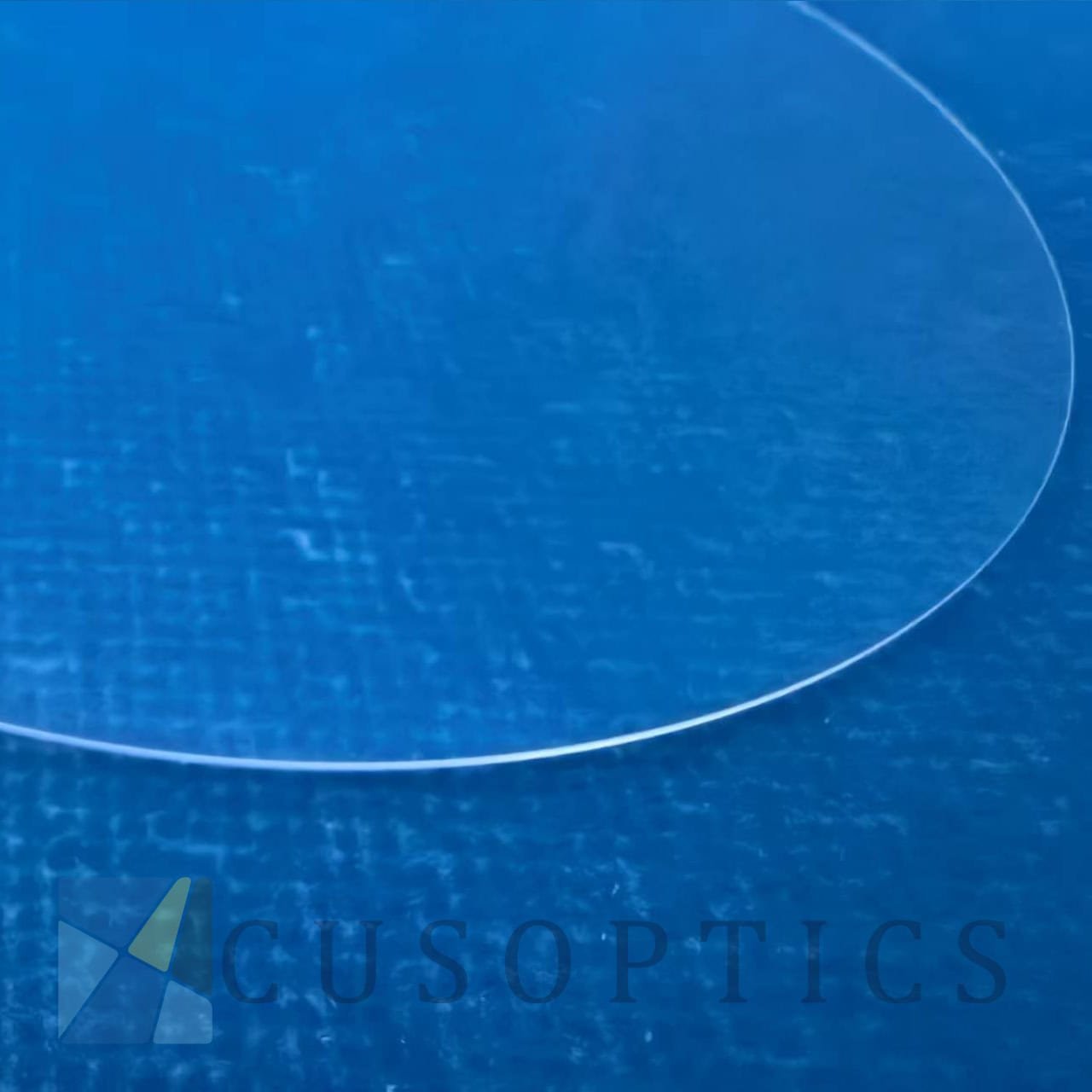

3. Double sided polishing:

Both main surfaces (front and back) of the chip have undergone precision polishing treatment.

Purpose and advantages:

Extremely high surface smoothness and flatness: removing surface damage layers and micro defects, achieving nanometer or even sub nanometer level roughness.

Excellent parallelism: Ensuring that two surfaces are highly parallel is crucial for optical and certain epitaxial applications.

Low defect density: reduces surface scratches, pits, etc., improves material performance and yield.

High transmittance: For optical applications such as window panels, polishing greatly reduces light scattering loss and improves transmittance.

Provide a perfect substrate for subsequent processes: provide defect free starting surfaces for precision processes such as photolithography, thin film deposition, and bonding.

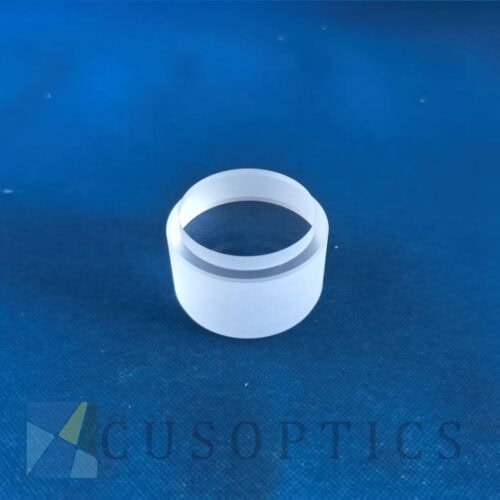

4. Corner cutting:

The cutting of the edge of a chip with a specific angle (usually a slope), rather than a simple right angled edge.

Purpose and advantages:

Preventing edge cracking: This is the primary objective. Sapphire is hard but brittle, and its right angled edges are prone to small chipping or cracks (known as “chipping”) during subsequent handling, cleaning, photoresist spin coating, high-temperature processes, and other processes. These broken edges will become stress concentration points, causing the chip to fracture during subsequent processing or use, resulting in losses. Chamfering can effectively disperse stress and greatly reduce the risk of edge breakage.

Improving mechanical strength: reducing edge stress concentration and overall enhancing the mechanical robustness of the chip.

Improving the uniformity of photoresist coating: Right angled edges can easily lead to uneven accumulation or retraction of photoresist at the edges, and corner cutting helps to obtain a more uniform photoresist film layer.

Compliant with automation equipment requirements: Modern semiconductor and LED manufacturing automation equipment (such as robotic arms) have requirements for the shape of chip edges, and corner cutters are more compatible.

5. Large size:

Usually refers to chips with a diameter of 4 inches (100mm) or more. Common large sizes include 4 inches (100mm), 6 inches (150mm), and even larger (such as 8 inches/200mm appearing in research and development or specific applications).

Meaning and advantages:

Higher production efficiency: More devices (such as LED chips) can be manufactured on a single chip, significantly increasing output per unit production time and reducing costs (sharing fixed costs).

Meeting the requirements of high-power/large-area devices: For applications such as high-power LEDs, lasers, or large-area optical windows that require a large light-emitting area, large-sized substrates are necessary.

The manifestation of technological progress: growing large-sized, high-quality, and low defect density sapphire crystals and processing them into large-sized chips represents a high level of material growth and processing technology.

Industry trend: With the maturity of technology and the reduction of costs, LED、 The display (Mini/Micro LED) and other industries are actively transitioning to sizes of 6 inches and above.

The main characteristics of sapphire glass

The main characteristics of sapphire include high hardness, high scratch resistance, high transparency, high temperature resistance, etc., so it is widely used in many high-end applications.

- Scratch resistance: sapphire glass is made of artificial sapphire crystal, with extremely high hardness, can resist scratches and wear in daily useto maintain the clarity and gloss of the glass surface.

- Transparency and optical performance: sapphire glass crystal has a high degree of transparencyand can transmit more light, so that it has a wide range of applications in the field of observation and display. Transmittance band: 185 ~ 5000nm

- High temperature resistance: the melting point of sapphire glass is 2045°C, and the application temperature is generally below 2000°C.

- Pressure resistance: As a kind of high-strength glass, the compressive strength of sapphire glass at room temperature can reach 2.1GPa, so it is used as a viewing window in deep sea diving.