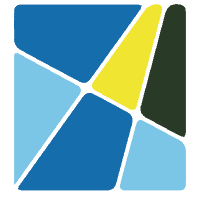

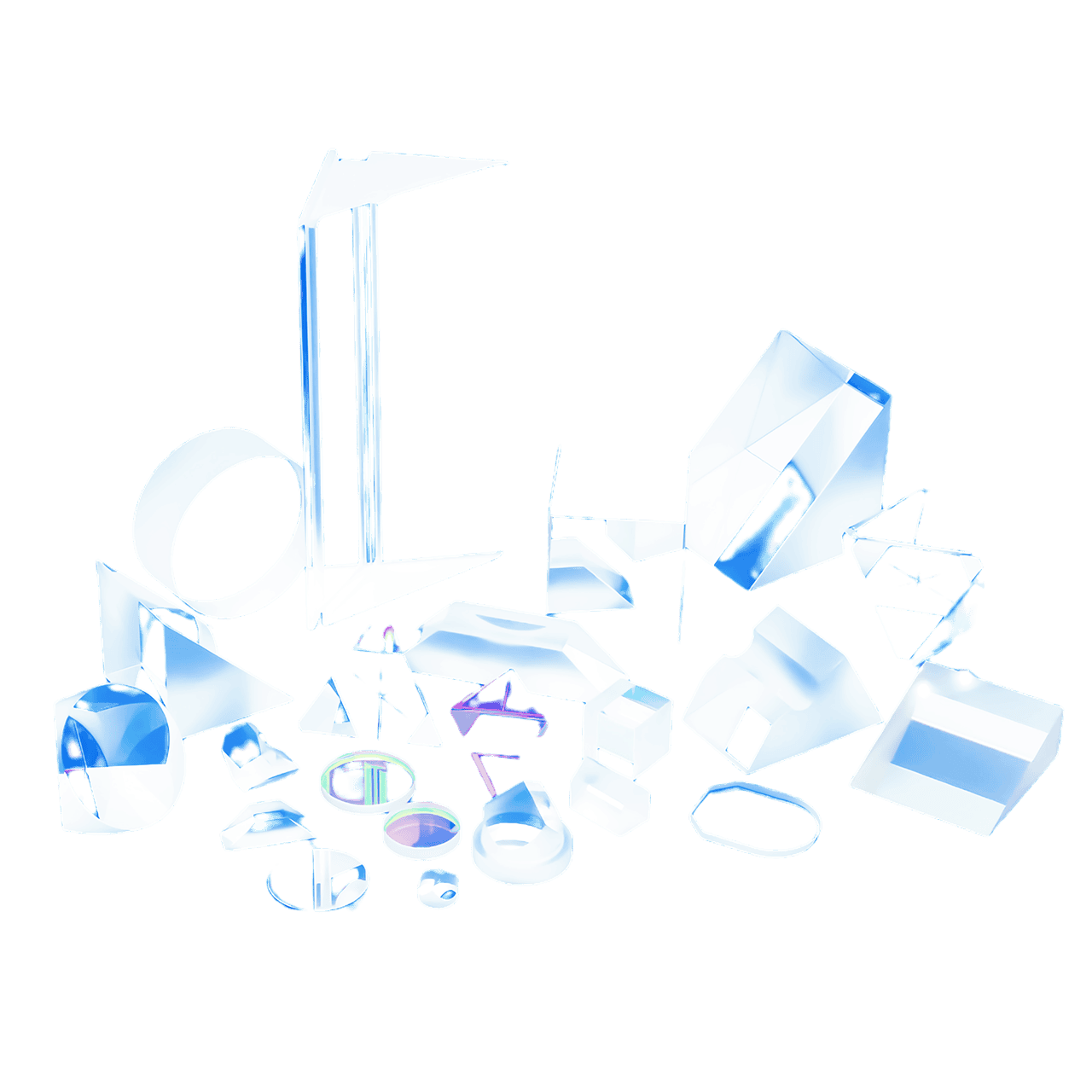

Optical Lens

Optical lenses are transparent components that refract and focus light. Made from glass or plastic, they are essential in cameras, telescopes, microscopes, and eyewear for correcting vision, magnifying images, and concentrating light beams.

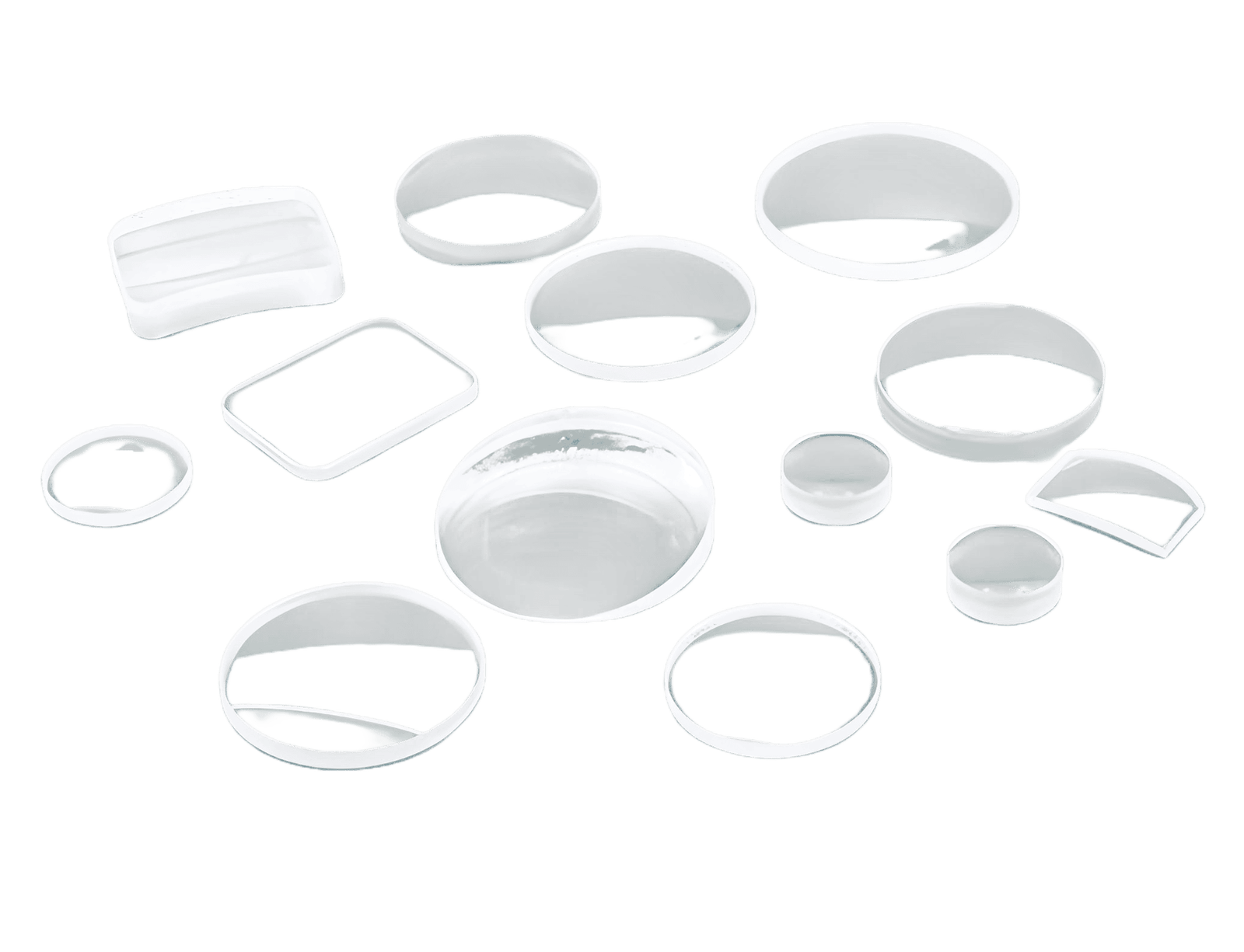

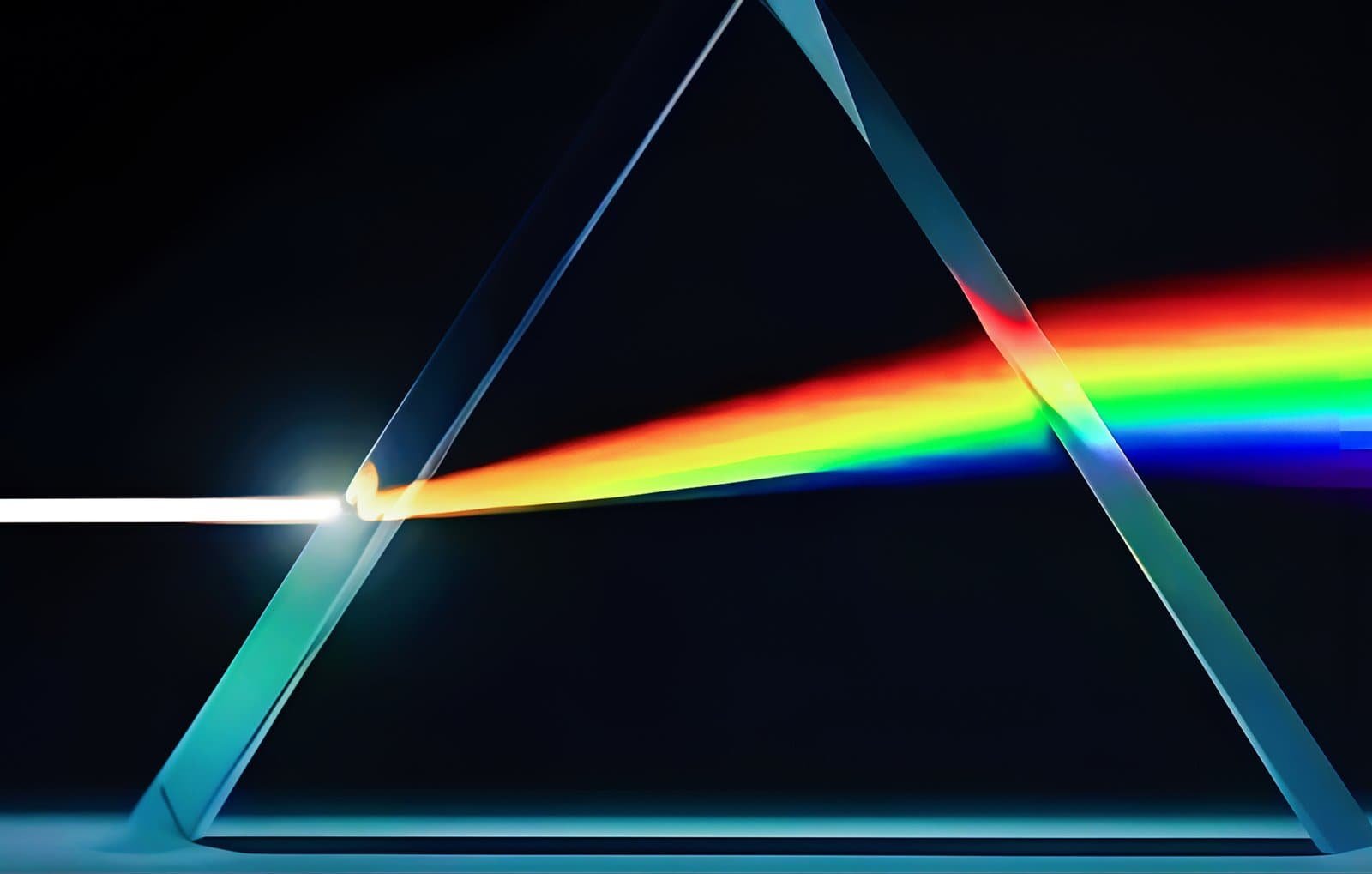

Optical Prism

An optical prism is a transparent element that refracts, reflects, or disperses light. Used in spectroscopy, imaging, and laser systems for beam steering, dispersion, and wavelength separation. Custom designs available.

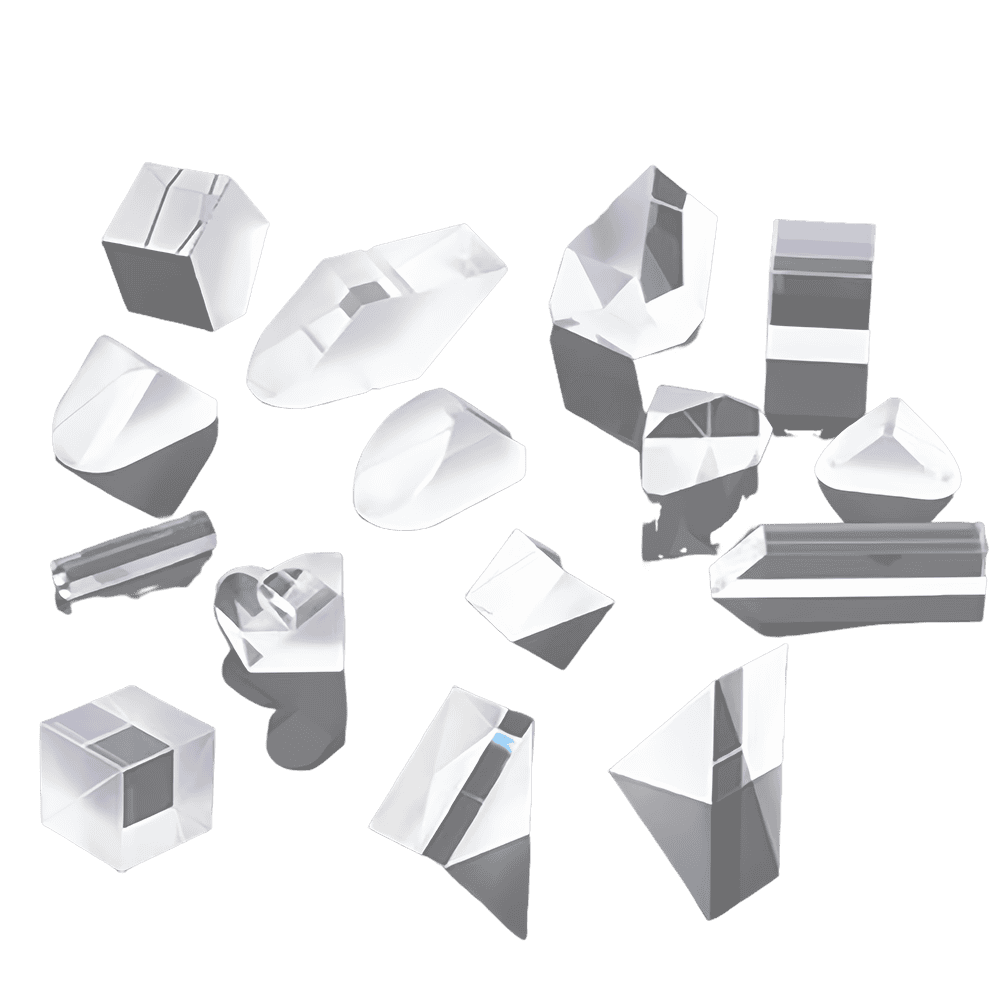

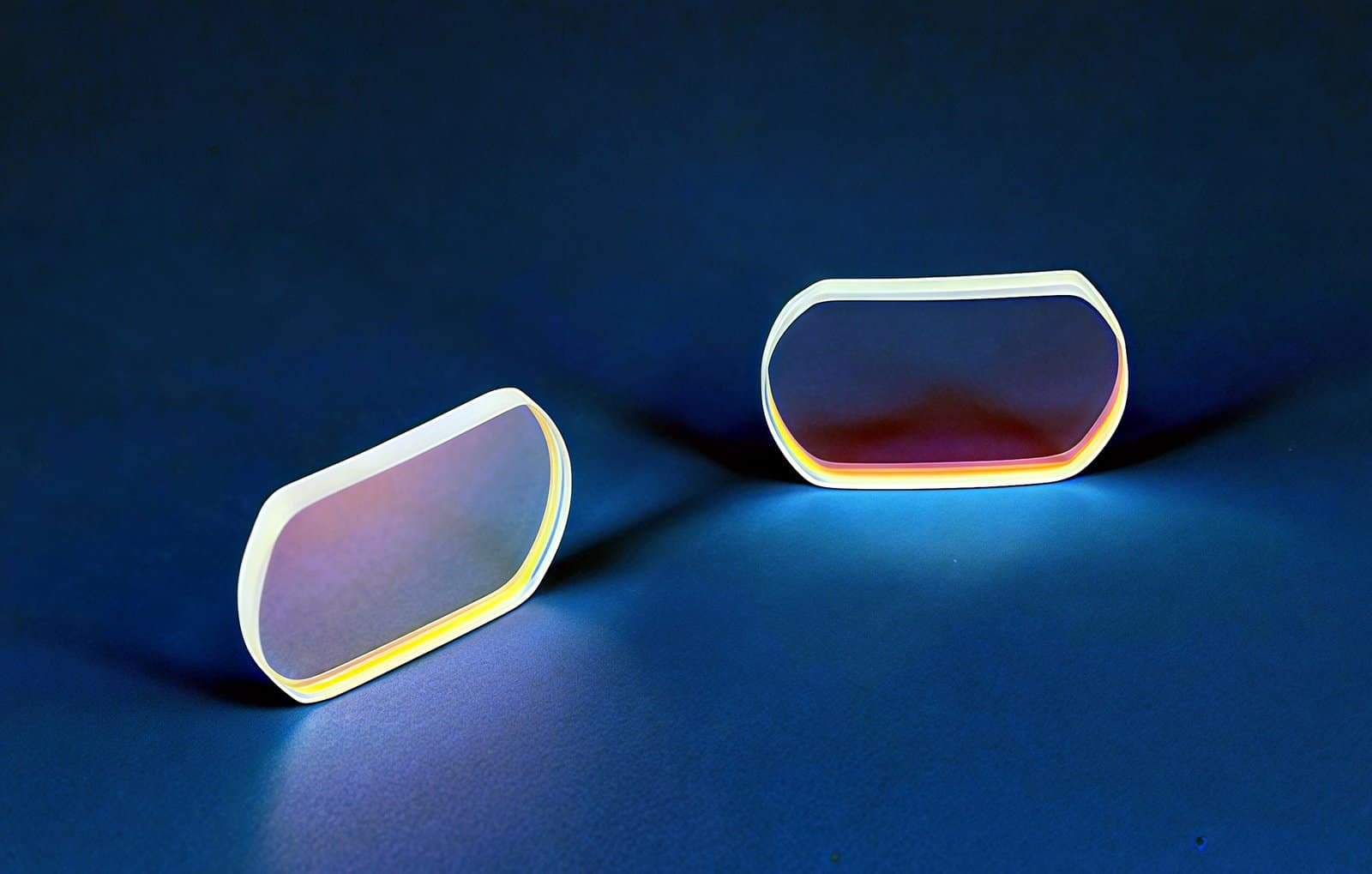

Optical Coating

Optical coatings like AR Coating, HR Coating, Beamsplitter Coating, Filter Coating & Protective Coating enhance light control, durability & performance in precision optical systems and components.

Sapphire Glass

Super high hardness(Mohs 9), super strong scratch resistance performance. High transparency, transmitting more light. Ultra high temperature resistance(application temperature of 2000°C).

Quartz Glass

High hardness (Mohs 6), High transparency, wide range of optical application bands (JGS1/JGS2/JGS3, application bands from 185nm to 3500nm), High temperature resistance, super strong acid and alkali resistance.

K9 Glass

Excellent transparency, refractive effect, hardness, and texture. A good optical substrate for coating. Easy to process into high-precision optical lenses and components (cutting, grinding, polishing and pressure casting).

How to work with us?

We will discuss and solve product application and detail issues with you in every detail. And without any worries, safely deliver the product to your hands. If you use our shipping, we will bear any unexpected losses of the product during transit.

How To Process Optical Glass

Optical glass involves different processing techniques

Why Work With Us?

Trusted by some of the clients…

Due to the particularity of optical glass products. We solve every problem for our clients throughout the entire cooperation process including potential product issues and losses during transportation. We have experienced technicians with many years of experience. We can provide technical consultation and analysis of material details. The prerequisite for establishing full trust with customers is communication. We will communicate details throughout each process of the order. We will treat every customer with sincerity and fully understand their needs.