Description

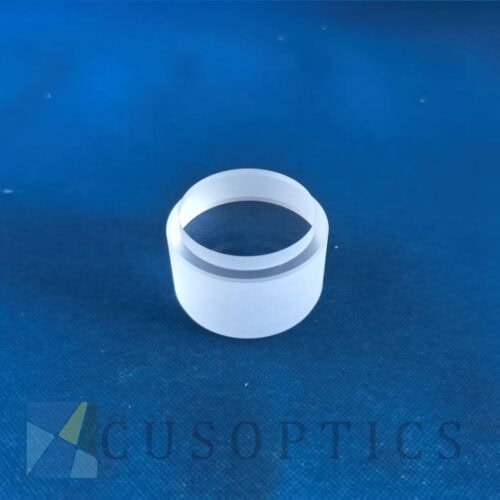

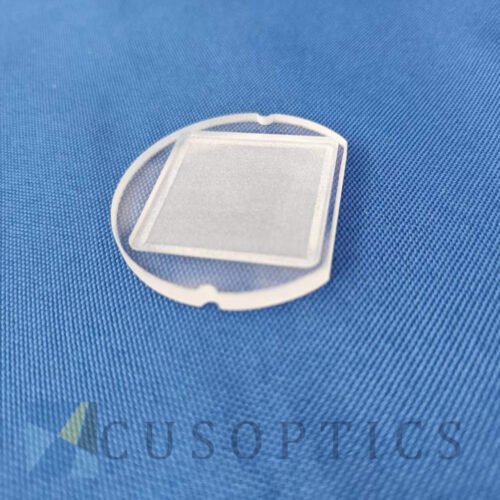

Rounded corner sapphire glass is a high-performance thin film component that combines top-notch wear-resistant material (artificial sapphire) with humanized safety design (rounded corners). It is widely used in products that require high durability, clarity, and aesthetics, and is one of the symbols of high quality and reliability.

1. Sapphire glass:

Material essence: It is not natural sapphire, but refers to synthetic sapphire single crystal. Its main chemical component is aluminum oxide.

characteristic:

Extremely high hardness: The Mohs hardness is as high as level 9, second only to diamond (level 10). This gives it extremely excellent scratch resistance, making it almost impossible for metals, gravel, and other materials in daily life to leave scratches on its surface.

High transparency: Excellent transparency and high visual clarity.

High wear resistance: After long-term use, the surface can still maintain a bright and new appearance.

Excellent impact resistance: Although high hardness means more brittleness, compared to ordinary glass, its structural strength is higher and it can better resist certain impacts (but it will still crack under extreme impacts).

Good chemical stability: resistant to acid and alkali corrosion, not easily aged or discolored.

High temperature resistance: The melting point is very high (about 2040 ° C), and the heat resistance is good.

Application areas: Widely used in high-end watch mirrors, smartphone camera protective lenses, mobile phone screens (some high-end models), precision instrument windows, industrial equipment windows, bulletproof glass outer layers, luxury accessories and other scenarios that require extremely high wear resistance and clarity.

2. Rounded corners:

Shape feature: Refers to the edge or corner of a glass sheet being polished into a circular arc shape.

Purpose and advantages:

Safety: Avoid scratches or bumps that may be caused by sharp right angles. This is particularly important on handheld devices or items worn close to the body, such as watches.

Aesthetics: Rounded edges are often considered softer, more modern, and more design oriented.

Structural strength: Compared to sharp corners, rounded corners can better distribute stress and reduce the risk of cracking from the corners when impacted.

Process considerations: For sapphire, a high hardness material, processing sharp corners is extremely difficult and prone to edge breakage. Rounding corners is a more feasible and reliable edge treatment method.

Texture: The rounded edges feel more comfortable and smooth to touch.

The main characteristics of sapphire glass

The main characteristics of sapphire include high hardness, high scratch resistance, high transparency, high temperature resistance, etc., so it is widely used in many high-end applications.

- Scratch resistance: sapphire glass is made of artificial sapphire crystal, with extremely high hardness, can resist scratches and wear in daily useto maintain the clarity and gloss of the glass surface.

- Transparency and optical performance: sapphire glass crystal has a high degree of transparencyand can transmit more light, so that it has a wide range of applications in the field of observation and display. Transmittance band: 185 ~ 5000nm

- High temperature resistance: the melting point of sapphire glass is 2045°C, and the application temperature is generally below 2000°C.

- Pressure resistance: As a kind of high-strength glass, the compressive strength of sapphire glass at room temperature can reach 2.1GPa, so it is used as a viewing window in deep sea diving.