Description

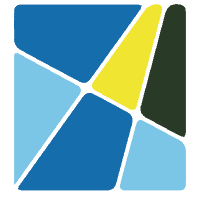

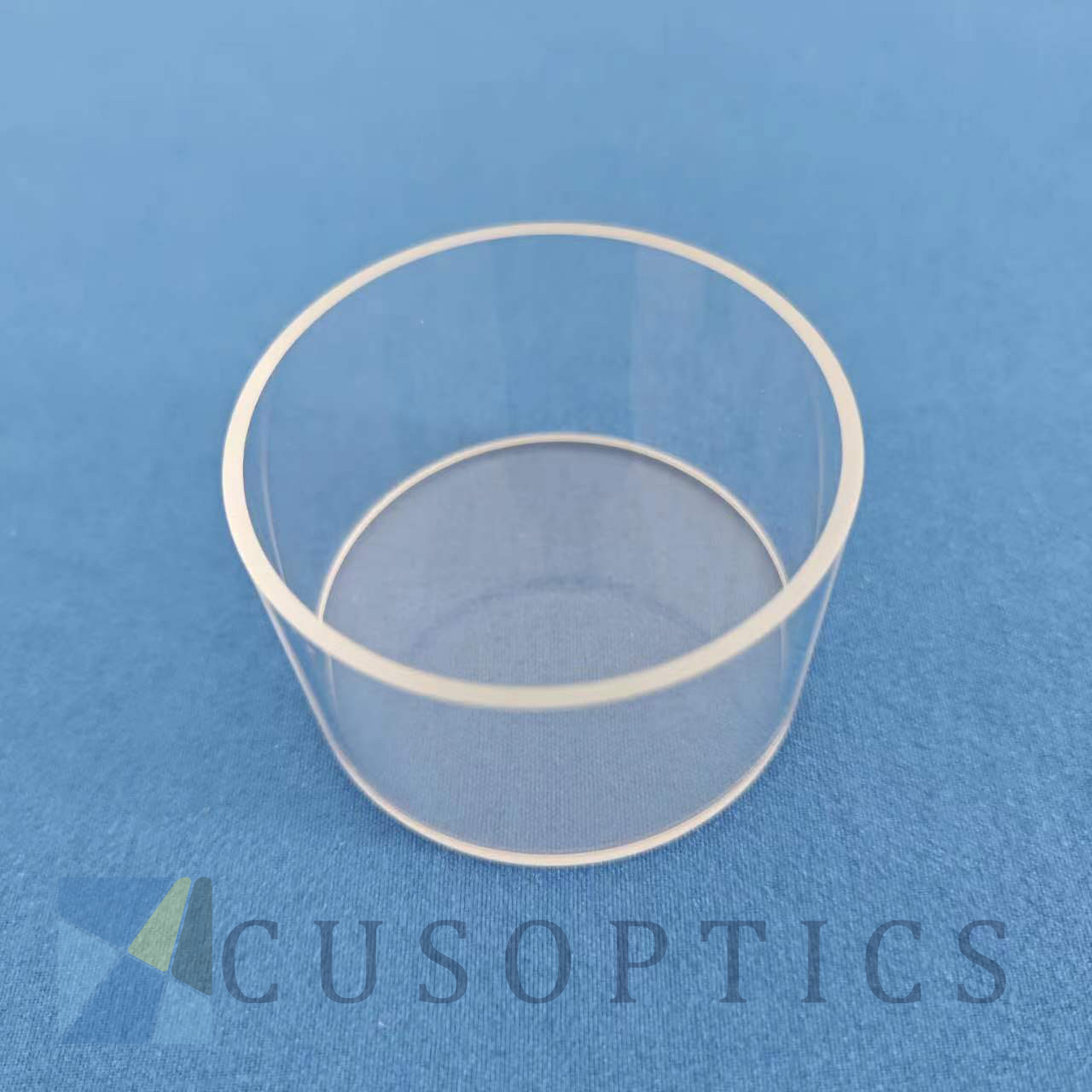

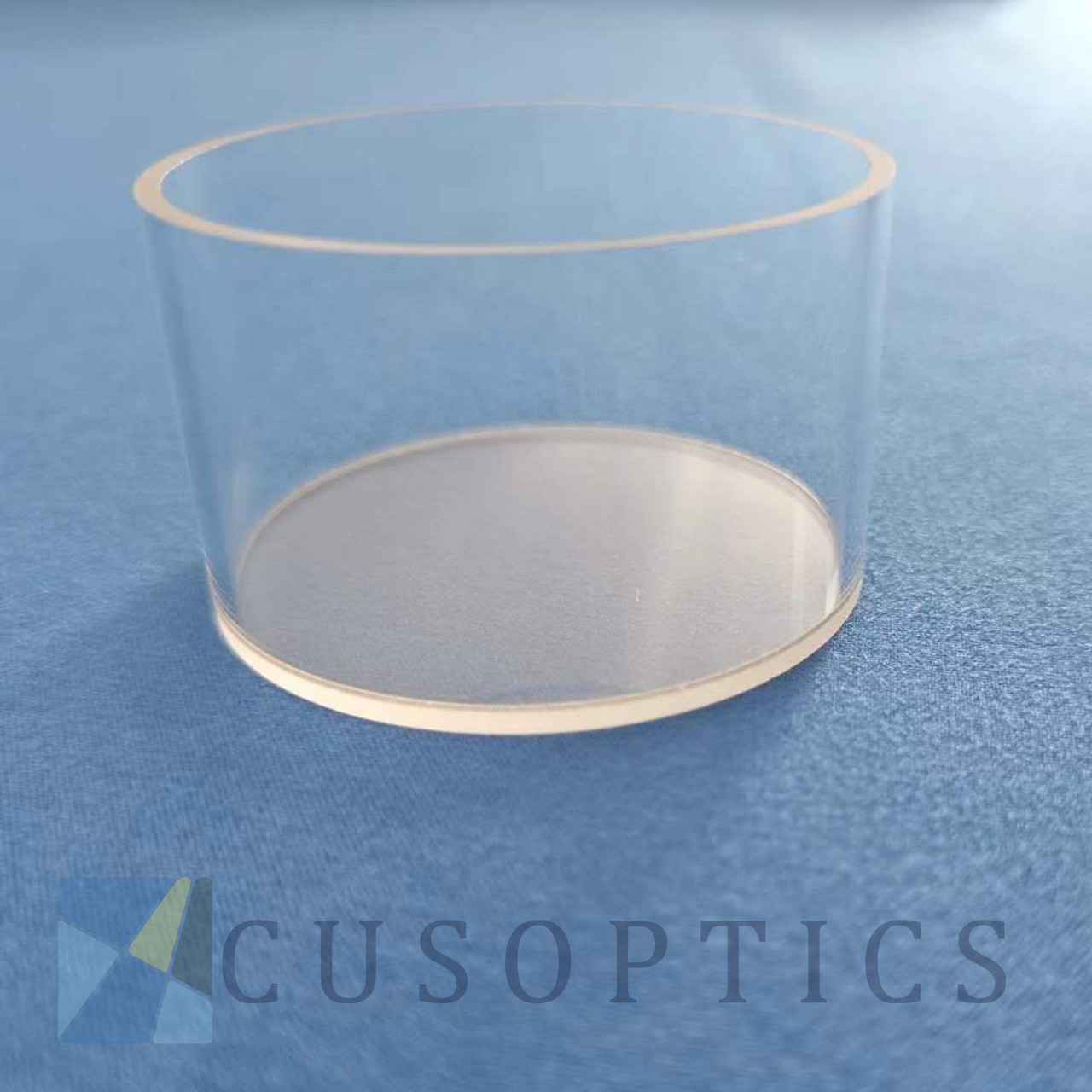

Quartz Optical Round Cuvette

This quartz cuvette uses the welding process of quartz powder melting at high temperature. The advantages of this welding technique are very obvious. The quartz sheet at bottom can be strengthened effectively, preventing it from falling off easily. Additionally, the light transmission area of the quartz sheet is enlarged while ensuring that the light is not dispersed at the edges. Although the strength of this welding product is slightly lower than that of full fusion welding, it is the best welding technique for products for optical use. The quartz glass sheet at bottom can also be replaced with glass sheets of other materials. In general, we recommend using optical quartz glass of the same material, such as quartz glass JGS1, JGS2, and JGS3.

The main characteristics of quartz glass

- Heat resistance

The softening point of quartz glass is 1730 ℃. It can be used for a long time below 1100 ℃, and the temperature for short time use is up to 1450 ℃.

- Light transmission

Quartz glass has good light transmittance in the entire optical spectrum from ultraviolet to infrared, and the visible light transmittance is more than 93%, especially in the ultraviolet spectral region, the maximum transmittance can reach more than 80%.

- Electrical insulation

The electrical resistance of quartz glass is equivalent to 10,000 times that of ordinary glass.

- Chemical stability

Quartz glass almost don’t react chemically with other acid-base substances except hydrofluoric acid.

- Thermal stability

Quartz glass has low expansion coefficient, and it can withstand drastic temperature changes.

- Hardness characteristics

With the hardness of Mohs level 7, the mechanical properties of quartz glass are better than hard glass and ceramics, and the strength of quartz glass improves with the increase of temperature, reaching its maximum when approaching the annealing temperature.