Description

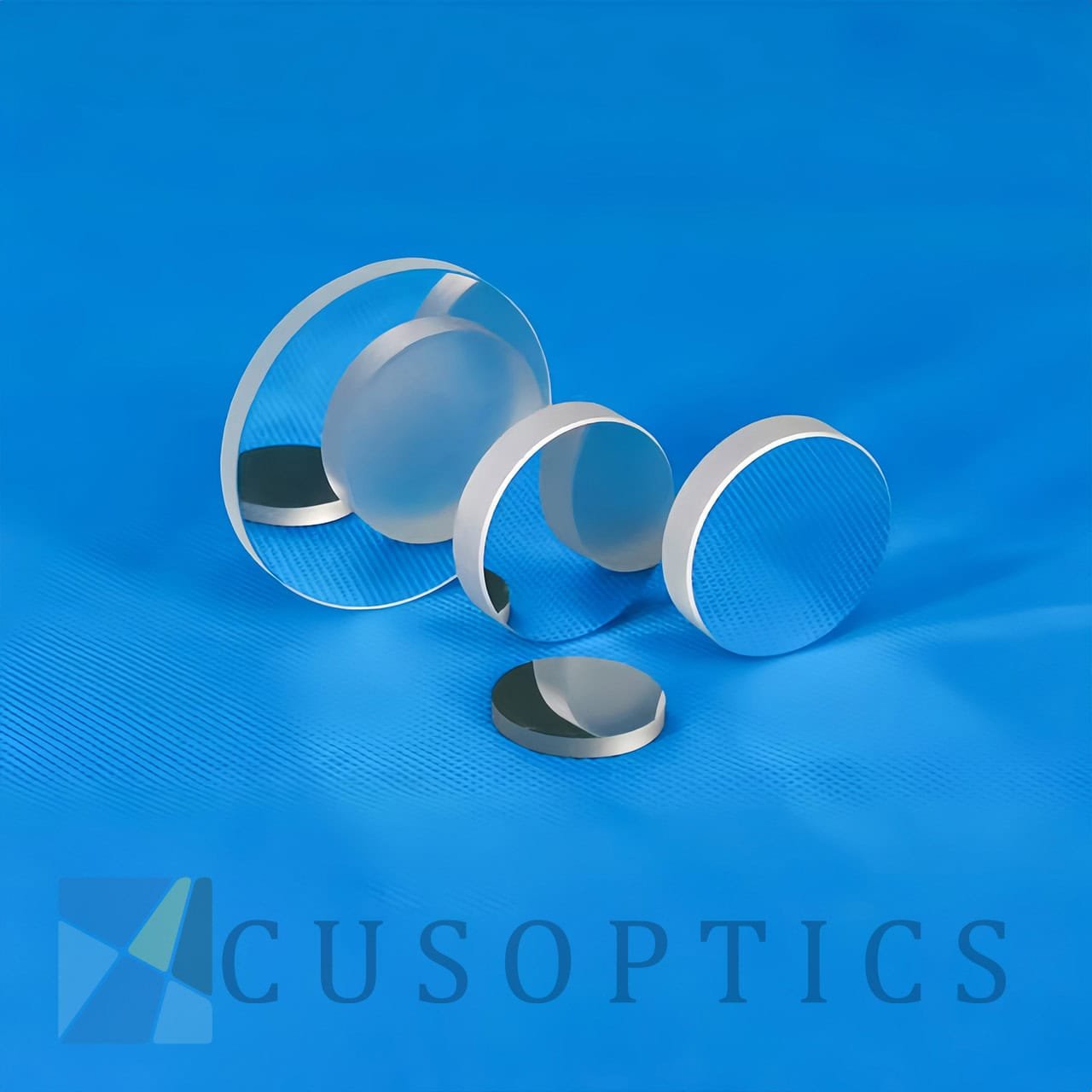

An Aluminum Coated Mirror is a fundamental Optical Mirror created by depositing a high-purity aluminum film onto a precision-polished substrate. Its key feature is being a First Surface Mirror, where reflection occurs at the front surface, eliminating ghost images and making it an Interference Free Mirror crucial for high-fidelity applications.

These mirrors are quintessential Beam Steering Mirrors in Laser systems and optical assemblies. Standard versions offer broad-spectrum High Reflectivity. For durability, a Protected Aluminum Mirror features a dielectric overcoat (e.g., SiO₂) guarding against oxidation and abrasion. Performance can be tailored with an Enhanced Aluminum Mirror design, which is often UV Enhanced to maximize reflectance in specific ultraviolet or infrared bands.

The substrate choice is critical. Economical options use Borosilicate Glass, like the common BK7 Aluminum Mirror or N-BK7 Aluminum Coated Mirror. For superior performance, a Fused Silica Aluminum Mirror or Quartz Aluminum Mirror made from UV Grade material is essential. It provides exceptional thermal stability for high-power lasers and high transmission for deep-UV applications.

When sourcing, engaging a professional Aluminum Mirror OEM Supplier is advised. They can provide competitive Price quotes and manufacture to Custom Size and specification requirements, ensuring optimal performance for any optical system.

Optical Glass Coatings and Their Features

1. Anti-Reflective Coating (AR)

Minimizes light loss and eliminates ghosting by reducing surface reflections. Features include >99.5% transmission at target wavelengths, broadband performance across UV to IR spectra, and excellent durability against abrasion and environmental factors. Essential for lenses and displays.

2. High-Reflective Coating (HR)

Achieves extreme reflectivity (>99.9%) through dielectric layer stacks. Offers negligible absorption/scatter, high laser damage threshold, and precise wavelength specificity. Critical for laser cavities and mirror applications.

3. Beamsplitter Coating

Divides light into reflected/transmitted components with precise ratios (e.g., 50/50). Provides polarization-sensitive or wavelength-specific splitting. Used in interferometry and imaging systems.

4. Bandpass Filter Coating

Transmits narrow wavelength bands while blocking others. Features sharp cut-on/off edges, high out-of-band rejection (OD4+), and stable performance at various angles. Ideal for spectral analysis.

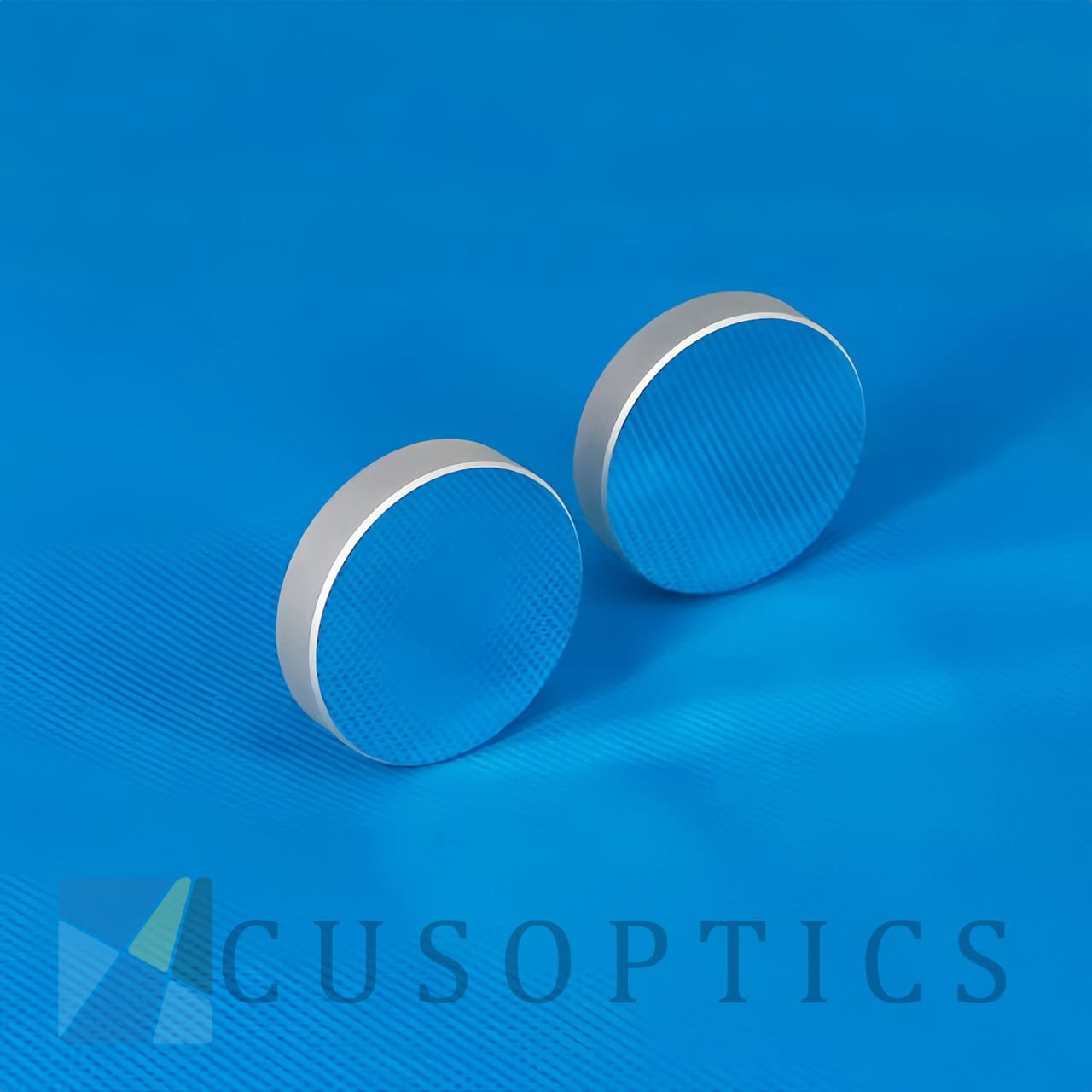

5. Metal Mirror Coating (Aluminum/Protected Aluminum)

Provides broad-spectrum reflection from UV to IR. Aluminum coatings offer ~90% reflectivity, while protected versions add durability through oxide overlayers. Cost-effective for general purpose use.

These coatings enable advanced control over light propagation, reflection, and spectral selection in optical systems, with specific formulations optimized for laser, imaging, or analytical applications.