Optical Coating

The types of substrates (base materials) for optical coating are very diverse. Choosing the right substrate is the foundation for successful coating. The selection of substrate mainly depends on optical properties, mechanical properties, chemical stability, cost and application environment.

Anti-Reflection Coating – AR Coating

The purpose is to reduce surface reflection light, increase transmittance, reduce shadows and glare & improve imaging contrast.

High-Reflection Coating – HR Coating

A functional thin film coated on the surface of optical components and designed to reflect incident light in a very high proportion (usually>95%, up to 99.99% or more).

The main purpose is to minimize the loss of light energy transmission and efficiently reflect light back into the optical system.

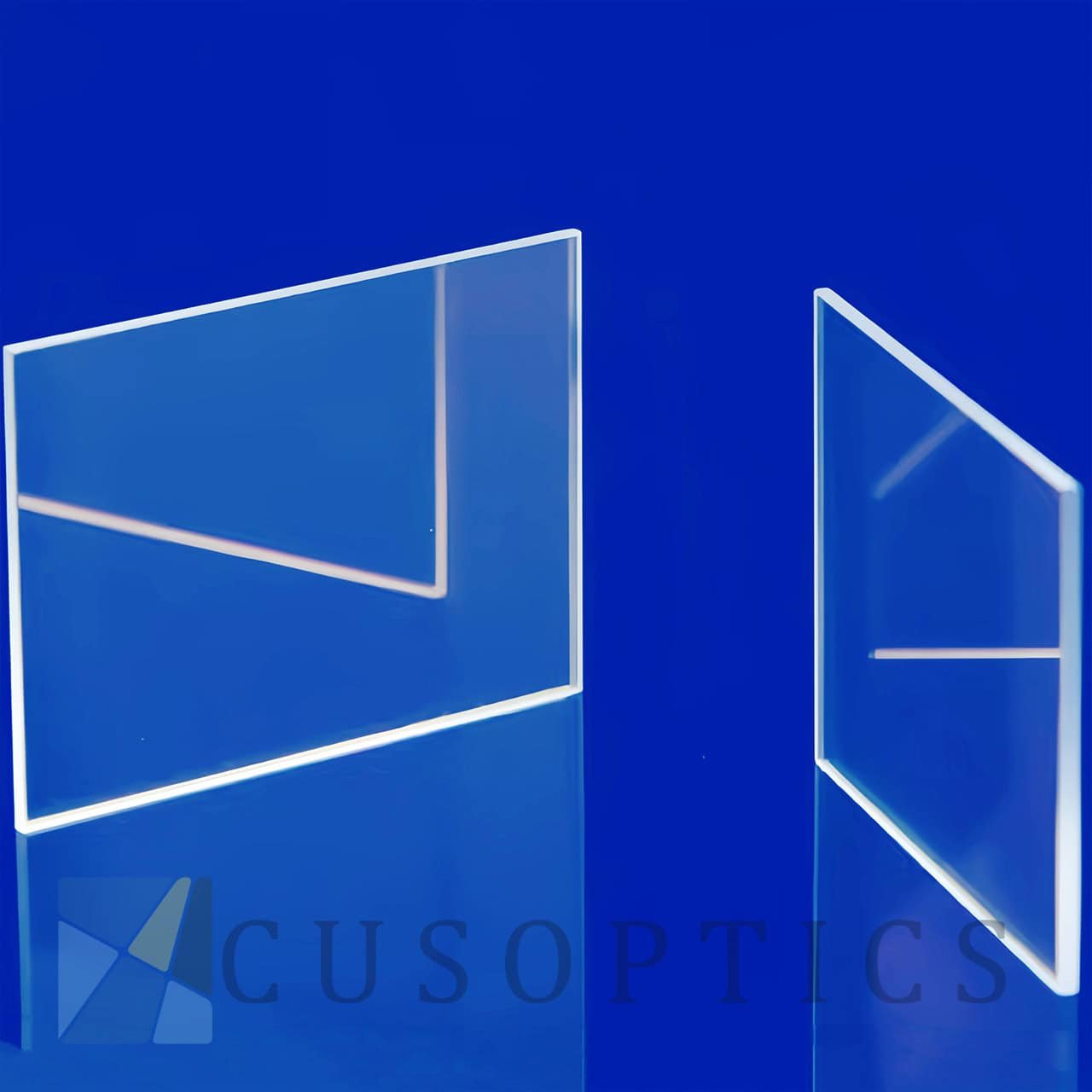

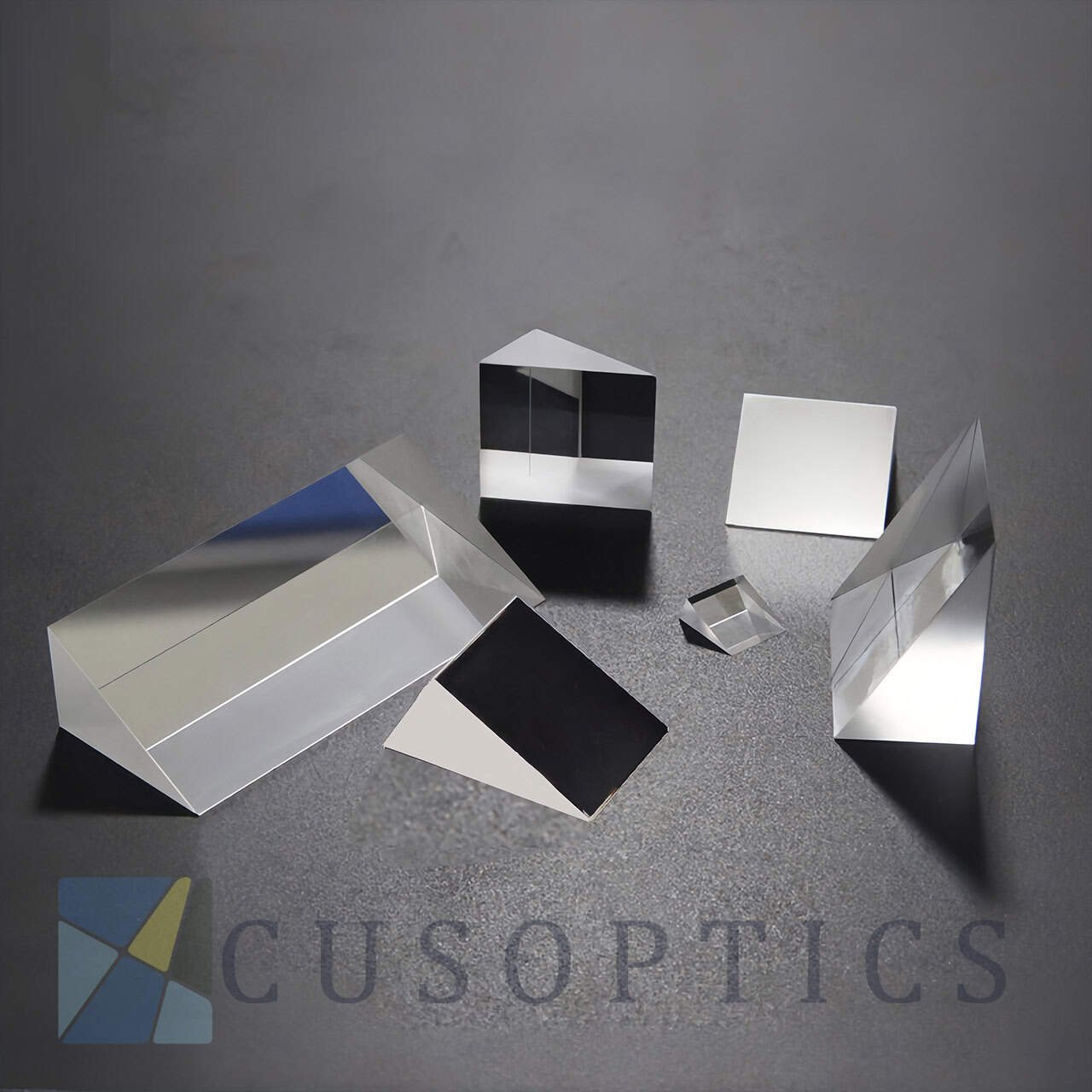

Beamsplitter Coating

A functional thin film coated on the surface of an optical element (usually a prism or a flat plate) and capable of dividing a beam of incident light into two beams of reflected and transmitted light in a specific ratio.

The main purpose is to precisely control the distribution of light energy, achieving light splitting, combining, or sampling.

Protective Coating

Protective film is a hard thin film mainly used for physical protection and improving environmental durability.

The main purpose is to protect the delicate functional film layer below (such as metal reflective film, anti reflective film) or soft optical materials (such as plastic). Prevent it from being scratched, worn, corroded or oxidized & extend its service life.