Lens Coating: Technical Principles and Classification AnalysisLens Coating: Technical Principles and Classification Analysis

- Lens coating technology

Since the emergence of optical lenses, advancements in surface treatment technologies have evolved through multiple innovations. Among these, lens coatings play a critical role by enhancing light transmittance, minimizing reflection, and improving visual comfort, particularly by mitigating the occurrence of false images under light source. As a key functional component, lens coatings not only influence the optical performance of the lenses but also significantly impact the wearer’s visual clarity and overall comfort.

In the absence of a coating, the light transmittance of resin lenses is limited to a range of 89% to 92%. However, the occurrence of multiple reflections of light results in the formation of a virtual image above the light source, thereby impacting the visual effect. The implementation of lens coating is an effective method of mitigating such reflections, enhancing light transmittance, and ensuring a more comfortable and clear visual experience for the wearer.

- Technical principle of lens coating

The application of coating is accomplished through the utilization of optical films and vacuum technology to achieve a precise thickness of optical film on the lens surface, thereby optimizing the regulation of light reflection and augmenting the performance of the lens. This technology aims to enhance the ability of the lens to control reflected light, thereby increasing or decreasing the transmission of light and raising the light transmittance of the lens to up to 98%. In comparison with uncoated lenses, the clarity of the latter has been significantly enhanced.

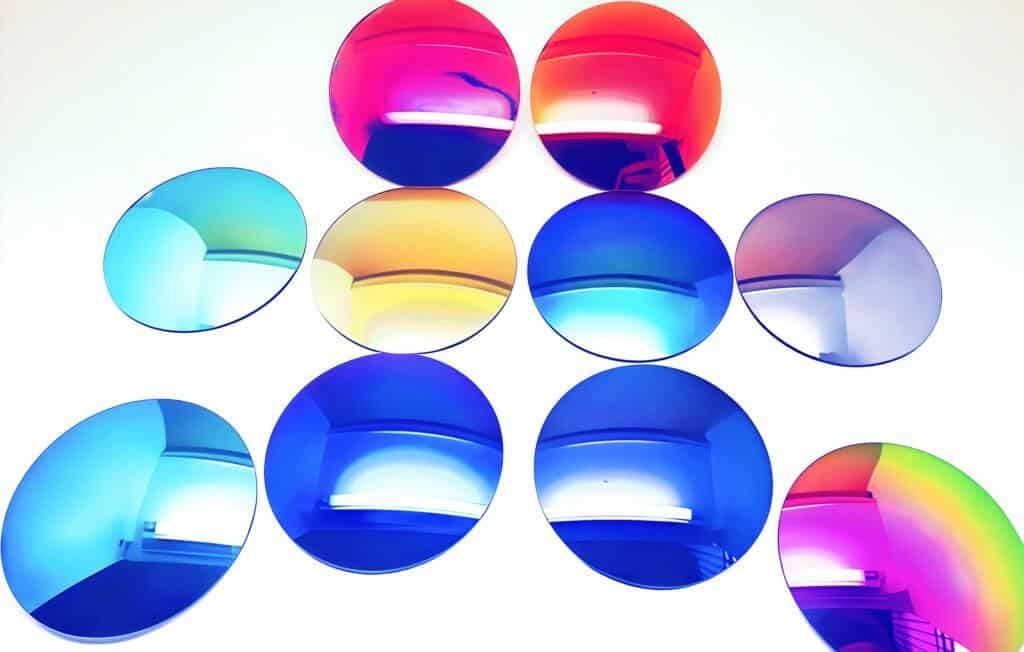

- Basic typesof film coating

- Hardening film

The first type is hardening film, whose primary function is to enhance the abrasion resistance. The use of materials such as silica in the hardening film serves to enhance wear resistance and extend the lifespan of the lens. This type of film is typically composed of hardening materials such as silica or silicone, which are polymerized through immersion and subsequently coated onto the lens surface to prevent scratching. Additionally, it can be applied directly to the lens substrate, eliminating the need for an extra coating layer. This significantly increases the lifespan of the lens.

- Anti-reflective film

Another important type of film is the anti-reflective film, whose main function is to increase light transmittance. This kind of film is usually prepared by the vacuum coating method, which involves evaporating and spraying substances like lithium fluoride, magnesium fluoride and calcium fluoride onto the lens surface under vacuum conditions, thereby forming a multi-layer film structure. Anti-reflective film enhances light transmittance through a multi-layer structure, thereby reducing reflection and improving both the aesthetics and the usage safety of the coated surfaces.

- Advanced film coating technology

- Anti-blue light film

The anti-blue light film is a special coating applied to the lens surface, which reflects harmful blue light and thus offers protection against blue light. The anti-blue light film has been developed to reduce the damage caused by blue light to the eyes, especially when using electronic devices for extended periods.

- HD blue film technology

With the rapid advancement of technology, anti-blue light coating technology has also seen continuous improvement. Enhanced thin-film techniques now offer superior blue light blocking while maintaining high light transmittance, thereby improving wearing comfort and aesthetic appeal. The high-definition, low-reflection blue light film technology further ensures a clearer and more comfortable visual experience.