How to judge the abrasion resistance of K9 optical glass coated with anti-abrasion films?

K9 optical glass can be applied in the fabrication of lenses, prisms, mirrors and windows in optical instruments. The most fundamental method for evaluating and testing the wear resistance of K9 glass coated with an anti-abrasion film is through actual use. This entails the wearer wearing the K9 lens for a designated period and then conducting a detailed observation of the abrasion situation of lens using a microscope. Naturally, this is typically the approach utilized prior to the formal introduction of novel technologies, and the more rapid and intuitive testing methods that are now commonly used are as follows:

- Grindingtest

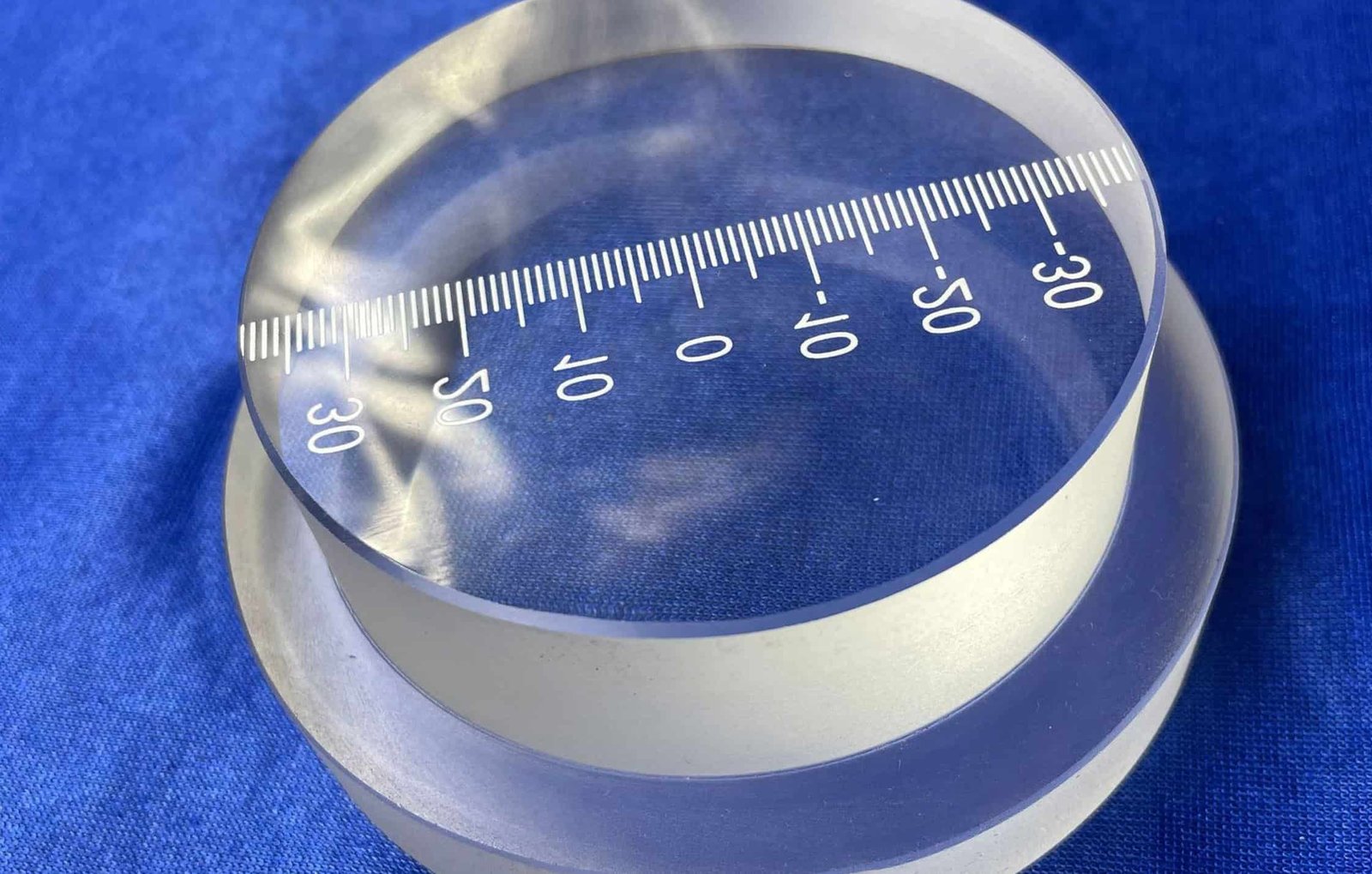

The K9 lens is positioned within a material comprising gravel, where the grit size and hardness is specified. The lens is then rubbed back and forth under specific control conditions. Subsequently, the diffuse reflection of light before and after the lens undergoes friction is quantified with a fog meter and compared with the standard lens.

- Steel wool test

A specified steel wool is used to grind the surface of the K9 lens under a certain pressure and speed for a specified time. The amount of light diffuse reflection before and after lens friction is then measured by a fog meter and compared with the standard lens. Alternatively, two K9 lenses can be manually rubbed together with the same pressure and number of times, and observing the results with naked eyes.

The results of the above two test methods are close to the actual outcome of the long-term use of K9 lens in the experiment.

- The relationship between anti-reflection film and anti-abrasionfilm

The anti-reflection film layer is a very thin inorganic metal oxide material (less than 1 micron in thickness), characterized by a high degree of hardness and brittleness. When plated on the K9 glass lens, the relatively hard lens substrate makes it difficult for scratches to form in the film layer. However, when the anti-reflection film is plated on other lenses, the lens soft base makes the film layer susceptible to scratching. Consequently, it is necessary to coat other glass lenses with an anti-abrasion film prior to plating an anti-reflection film, and ensure that the hardness of the two films is aligned.