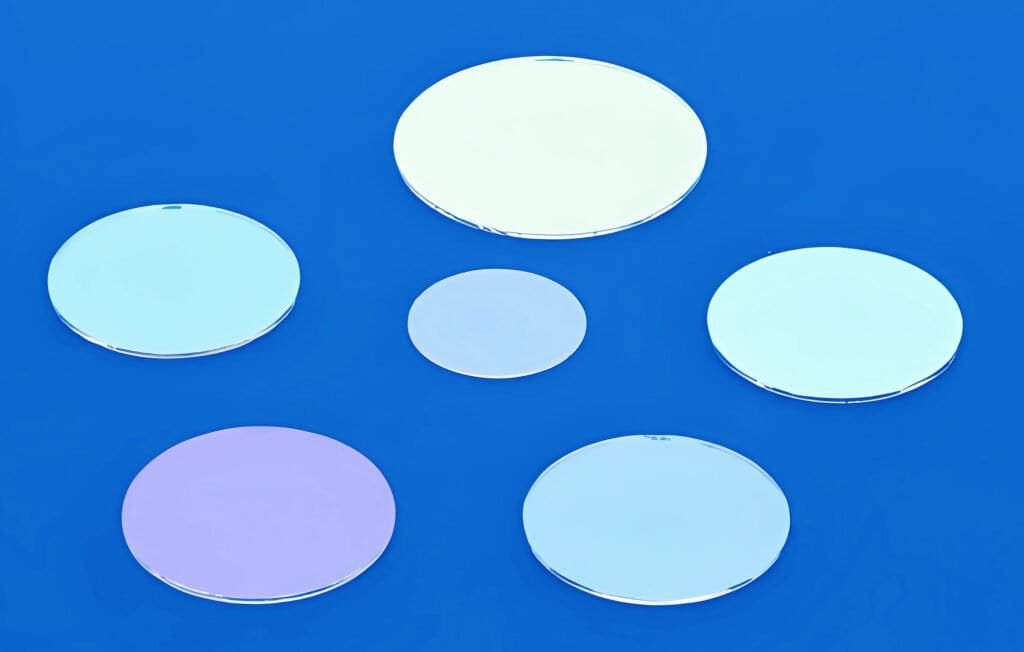

Functions, Advantages, Disadvantages of Coated Optical Glass

- The functionsof coated optical glass

- Optical separation

Coated optical glass facilitates wavelength-specific light separation, enabling precise dispersion control and spectral filtering. Through the design of multi-layer dielectric or metallic thin-film coatings, it achieves high transmission or reflection efficiency within targeted spectral wavelengths while effectively blocking unwanted wavelengths. This spectral separation is widely utilized in laser systems, optoelectronic devices, and telecommunications applications.

- Reflectionand transmission

After being coated with suitable metallic films or multi-layer dielectric films, optical glass can precisely manipulate the reflection, refraction, and transmission properties of light, thereby achieving optical effects such as high reflectivity, enhanced transmittance, and beam splitting. This capability facilitates the fabrication of optical components including reflectors, lenses, and attenuators. For example, anti-reflection film coatings can substantially reduce surface reflection losses on lenses, improve the light transmittance and imaging contrast of optical systems, and are widely used in high-precision optical instruments and photographic equipment.

- Filtering

Coated optical glass can be engineered to selectively transmit or reflect specific wavelengths, effectively suppressing unwanted stray light and thereby enabling the acquisition of purer optical signals or clearer images. This capability has been widely utilized in applications such as chemical analysis, microscopy, and digital imaging systems.

- Advantagesand disadvantages

- Advantages

Coated optical glass provides significant benefits including high efficiency, economic viability, and practical utility. The coating process is technically straightforward, characterized by rapid processing times and low operational costs, making it highly suitable for cost-effective mass production. Additionally, the application of coatings substantially improves the mechanical robustness and environmental stability of optical glass, notably enhancing surface hardness as well as abrasion and corrosion resistance.

- Disadvantages

Under off-design wavelengths or at large angles of incidence, significant degradation in transmission or reflection performance may occur. Furthermore, due to the mismatch in the coefficients of thermal expansion between the thin-film materials and the glass substrate, the coating is susceptible to cracking, delamination, or performance drift under conditions involving significant temperature variations or high humidity, thereby compromising the long-term stability of the optical component. Consequently, in applications involving extreme environments, such as aerospace, deep-sea, or high-temperature settings, careful consideration must be given to the design of the coating system and its environmental adaptability.

In summary, coated optical glass is extensively utilized in modern science, technology, and industrial applications, where it plays a critical role and offers notable advantages. Nevertheless, a comprehensive understanding of its limitations remains crucial. For different application scenarios, it is essential to selectively choose suitable coating materials, substrate properties, and coating process designs according to specific requirements. Furthermore, reliability validation should be conducted in conjunction with environmental factors to ensure optimal optical performance and functional effectiveness.