Application of Sapphire Glass in Chemical Equipment

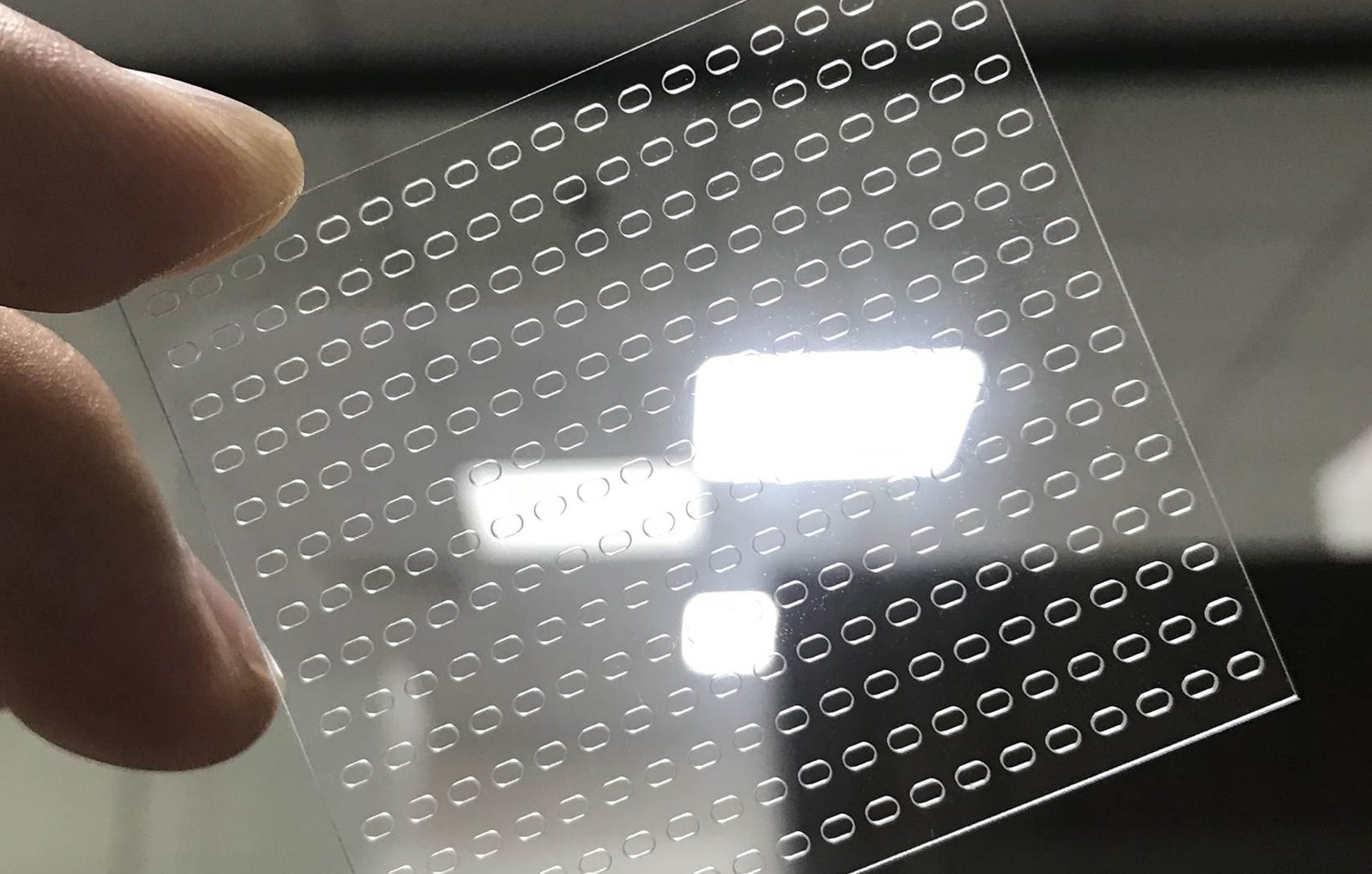

In recent years, the chemical equipment industry has experienced rapid advancements, leading to an increasing application of synthetic sapphire glass within this field. This innovative material exhibits exceptional physical and chemical properties, making it suitable for a diverse range of applications in various chemical sectors including pharmaceuticals, food processing, textiles, and biotechnology. This article aims to explore the utilization of synthetic sapphire glass in chemical equipment and the advantages it confers.

Firstly, the application of synthetic sapphire glass in chemical equipment significantly enhances the corrosion resistance and mechanical strength of the equipment. In chemical industry, many corrosive materials including acids, alkalis, and salts can severely corrode the chemical equipment, shortening its operational lifespan. Therefore, synthetic sapphire glass emerges as a superior alternative due to its remarkable resistance against strong acids and bases along with its high stability and weathering resistance, which ensures prolonged operational efficiency of the equipment. Furthermore, this material boasts elevated mechanical strength, hardness, wear resistance among other attributes which collectively contribute to reduced maintenance costs and downtime of equipment while simultaneously enhancing the production efficiency.

Secondly, the application of synthetic sapphire glass in chemical equipment significantly enhances product quality and production safety. In numerous chemical manufacturing processes, equipment corrosion not only reduces the operational lifespan of equipment but also leads to contamination of the final products. By utilizing synthetic sapphire glass as an equipment material, these issues can be effectively mitigated, thereby improving product quality and enhancing market competitiveness. Furthermore, this material exhibits excellent thermal resistance, allowing it to function reliably in high-temperature environments for a long time while ensuring both safety and stability throughout the production process.

Finally, the application of synthetic sapphire glass in chemical apparatuses has garnered support from environmental protection organizations. Unlike traditional materials, synthetic sapphire glass is free from heavy metals and organic pollutants, offering superior environmental performance. Additionally, its remarkable corrosion resistance and mechanical strength contribute to an extended service life for equipment while reducing the frequency of material replacements—making it a more environmentally friendly and sustainable option.

In summary, the utilization of synthetic sapphire glass in chemical equipment presents numerous advantages, significantly enhancing corrosion resistance, mechanical strength, and production efficiency of the equipment. Additionally, it contributes to improved product quality and safety while also enhancing the environmental performance of the equipment. It is anticipated that with ongoing advancements and innovations in new materials, synthetic sapphire glass will assume an increasingly pivotal role within the field of chemical equipment.