An Introduction of Sapphire—The Largest Demand Dield for High-Purity Alumina

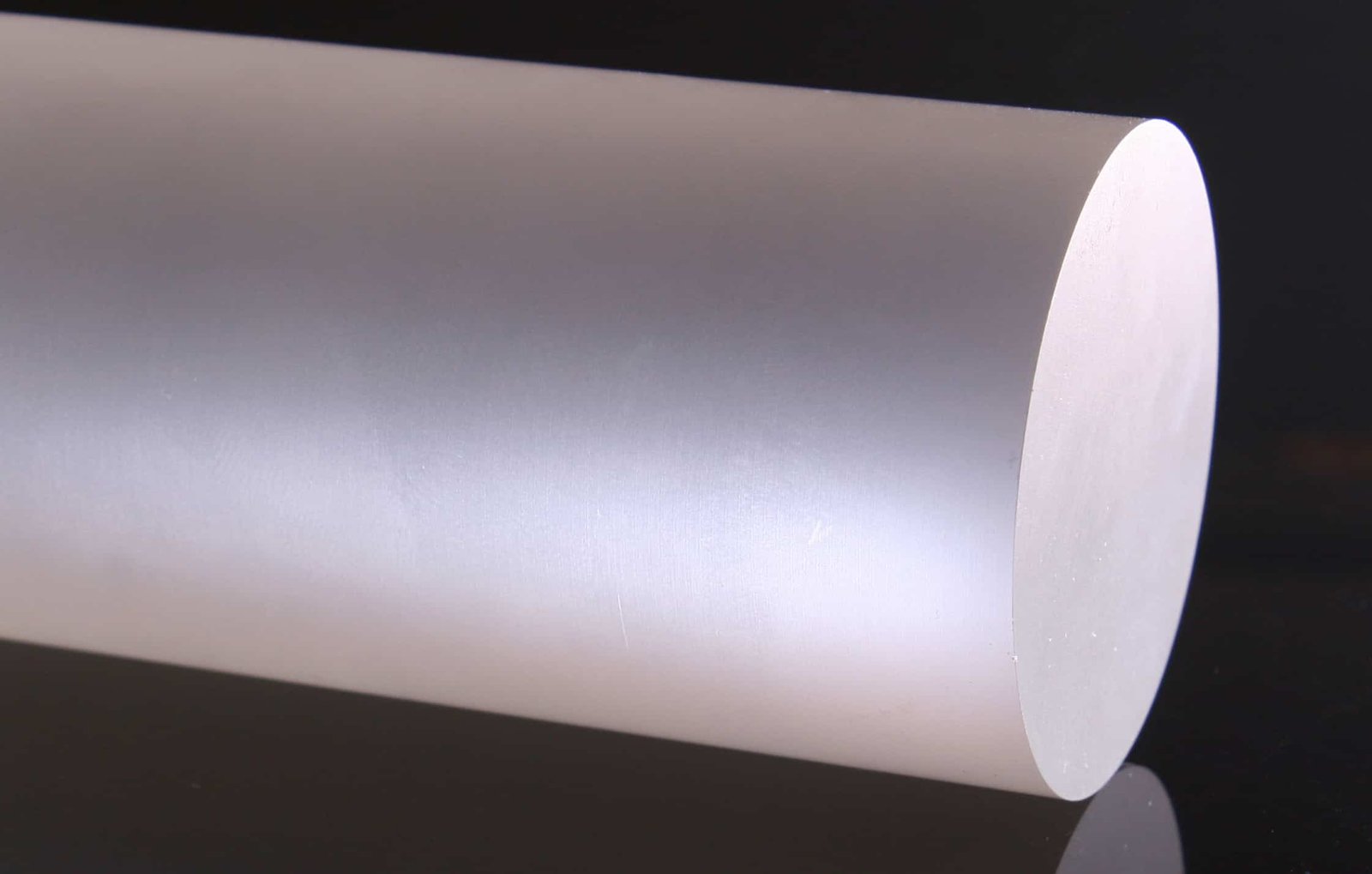

Sapphire crystal is grown from high-purity alumina powder with a purity exceeding 99.995%, making it the largest demand area for high-purity alumina. Due to its exceptional strength, hardness, and chemical stability, sapphire crystal can perform effectively in extreme environments characterized by high temperatures, corrosive conditions, and significant impact forces. Consequently, it finds extensive applications in fields such as national defense technology, civil technology, and microelectronics.

In the field of national defence, sapphire crystal is used primarily in the infrared window of missiles. In the context of contemporary warfare, the necessity for high precision in missile technology is paramount. The infrared optical window of missiles represents a pivotal component in achieving this precision. Considering that the missile will suffer from strong aerodynamic heat and impact force when it is in a high-speed flight environment, coupled with the harsh combat environment, the window of the missile must have high strength and anti-strike ability, as well as high resistance to the erosion of bad weather, such as wind with sand, rain, and so on. Sapphire crystal offers a number of advantageous properties, including good light transmittance, excellent mechanical properties and stable chemical properties. As a result, it is an ideal material for use in missile infrared windows.

The LED substrate represents the largest application of the sapphire crystal. The advent of LED lighting marks the third revolution in lighting technology, following the introduction of fluorescent lamps and energy-saving lamps, with the basic principle of converting electrical energy into light energy. When the current passes through the semiconductor, the hole and the electron are combined, resulting in the release of excess energy in the form of light, and that is the generation of luminous effect. The technology of LED chips is based on the epitaxial sheet, whereby layers of gaseous material precipitate on the surface of the substrate. The substrate material can be divided into three main categories: silicon, silicon carbide and sapphire. Among these, the sapphire substrate has a distinct advantage over the other two materials, mainly manifested in its high stability, well-established preparation technology, the absence of visible light absorption, favourable light transmittance, and competitive price. According to various data sources, approximately 80% of the world’s LED companies use sapphire as the substrate material.

In addition to the aforementioned applications, sapphire crystals can be utilized in mobile phone screens, medical equipment, jewellery decoration and other fields. They also serve as materials for the windows in scientific exploration instruments, such as lenses, and prisms.