Difficulties of K9 Glass Laser Cutting

Difficulties of K9 Glass Laser Cutting

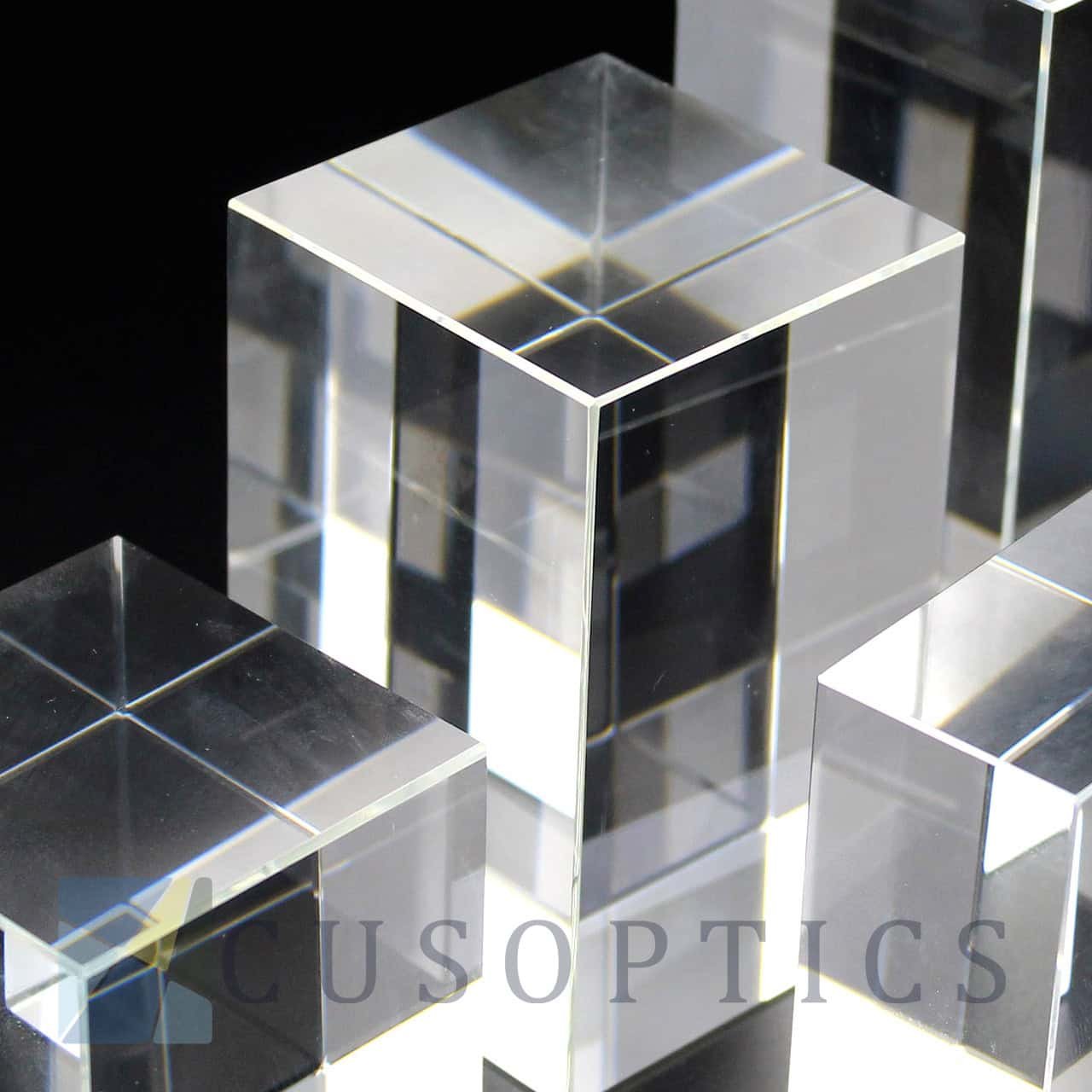

K9 glass, also referred to as K9 crystal, is a specific type of optical borosilicate glass. The letter “K” is derived from the German word for crown (Krone), while the number “9” is indicative of the lead oxide content of the glass (9%). It is a highly utilized material in optical systems, instruments and equipment due to its exceptional optical, thermal and mechanical properties.

- Properties of K9 glass

The high optical transparency, low dispersion, excellent thermal stability, high mechanical strength and chemical resistance of K9 glass make it the material of choice for a multitude of optical applications.

- Applications of K9 glass

K9 glass is an exemplary optical material, renowned for its exceptional optical properties and a vast array of applications. K9 glass serves a crucial function in the fabrication of lenses, windows, prisms, optical filters and other optical components, and is extensively utilized in photography, laser technology, scientific research, medical, communication, and other fields. The ongoing development and application of K9 glass will continue to drive the advancement of optical technology, thereby facilitating the provision of more innovative solutions for a range of industrial sectors.

- Difficultiesof K9 glass laser cutting

- Control of heat affected zones

The relatively low coefficient of thermal expansion of K9 glass means that even picosecond laser pulses can cause the formation of excessive heat-affected zones. Such effects will not only alter the physical properties of the glass, including the refractive index, but may also result in melting and recrystallisation of the cutting edge, thereby influencing the quality of the cutting process.

- Optimization of material removal rate

In laser cutting, the question of how to efficiently remove materials without damaging the glass is a significant challenge. The use of excessive laser energy may result in the fracture of the K9 glass. Conversely, the application of insufficient laser energy may lead to an inadequate cutting depth and the formation of an incomplete or impenetrable cut.

- Balance of cutting speed

In order to achieve optimal cutting quality, it is essential to align the cutting speed with the laser energy density. If the cutting speed is excessive, the laser may be unable to exert its full effect on the K9 glass. Conversely, if the cutting speed is insufficient, the resulting heat energy may accumulate to an extent that causes unnecessary thermal damage.