Description

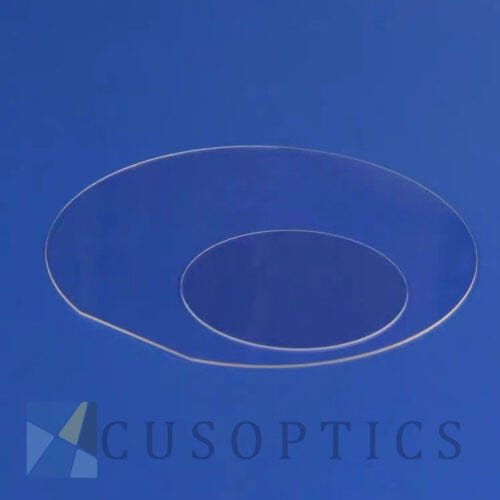

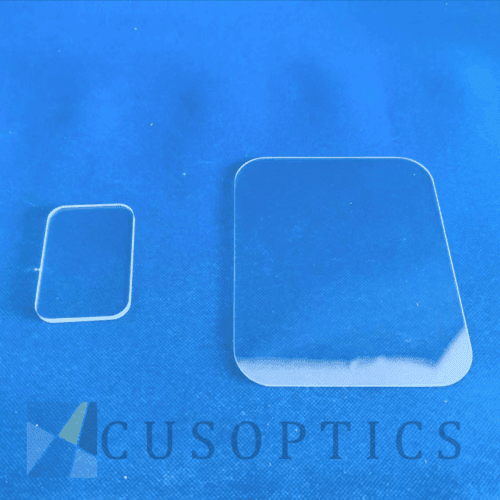

Micro Sapphire Glass Discs : Plates with Laser Drill Hole

Micro Small sapphire discs are generally extremely thin in thickness. Such a thin sapphire disc or plate cannot be drilled through CNC machining. Usually, thin discs are drilled by laser. The accuracy of laser drilling is very high. Like laser cutting, laser drilling is less prone to edge collapse. For thicker sapphire glass processing, laser processing can also meet high precision requirements. However, the cost of laser cutting is relatively high. For machining sapphire parts with low precision requirements, CNC machining remains a priority option.

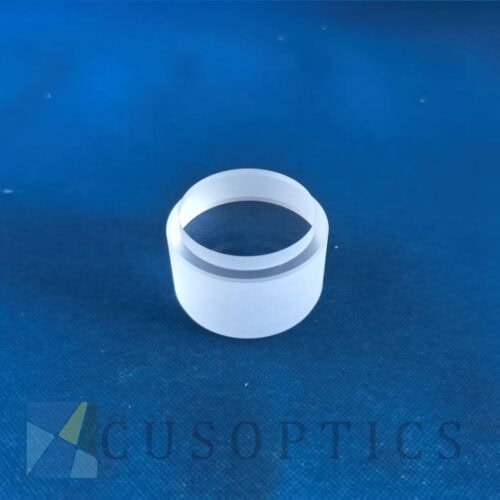

The main characteristics of sapphire glass

The main characteristics of sapphire include high hardness, high scratch resistance, high transparency, high temperature resistance, etc., so it is widely used in many high-end applications.

- Scratch resistance: sapphire glass is made of artificial sapphire crystal, with extremely high hardness, can resist scratches and wear in daily useto maintain the clarity and gloss of the glass surface.

- Transparency and optical performance: sapphire glass crystal has a high degree of transparencyand can transmit more light, so that it has a wide range of applications in the field of observation and display. Transmittance band: 185 ~ 5000nm

- High temperature resistance: the melting point of sapphire glass is 2045°C, and the application temperature is generally below 2000°C.

- Pressure resistance: As a kind of high-strength glass, the compressive strength of sapphire glass at room temperature can reach 2.1GPa, so it is used as a viewing window in deep sea diving.